Have you ever wondered how your mattress is made? From the moment you purchase it to the time it’s ready to sleep on, there’s a lot of work that goes into making mattresses. In this article, we’ll explore what goes into making a mattress and how the process works.

From raw materials to finished product, mattress makers have to ensure their mattresses are comfortable, safe, and long-lasting. To do this, they must use quality materials and pay close attention to detail. So just what does it take for a mattress to go from an idea to reality? Let’s find out!

Innovations in technology have allowed for new and improved bedding materials with different levels of firmness and support. Mattress makers now have access to cutting-edge fabrics that provide comfort while also being resistant to allergens and dust mites. This means you can get a top-of-the-line mattress without sacrificing on quality or comfort! Now let’s dive into the specifics of how mattresses are made.

Types Of Mattresses

Choosing the right mattress can be overwhelming with the many types available. Memory foam mattresses are popular for those looking for a comfortable sleep, as they contour to the body and distribute weight evenly. Innerspring mattresses are also popular, composed of coils or springs and a fabric covering. Latex mattresses provide support without sagging and are great for allergy sufferers due to their dust mite-resistant properties. Foam mattresses are made of polyurethane foam and offer good support when combined with other materials like wool or cotton. Mattress toppers provide an extra layer of cushioning between a mattress and a person’s body, while mattress pads protect against dirt and fluids that may seep through sheets. Double sided mattresses allow users to turn or flip them over for longer lasting use.

Nowadays, there is something for everyone in terms of mattress types; from latex mattresses that provide breathability to memory foam mattresses that contour your body for maximum comfort. Coil springs offer optimum support and can last many years if properly cared for. Mattress pads absorb moisture while mattress toppers add extra cushioning to the sleeping surface. Double sided mattresses extend the life of your bed by allowing you to turn them over periodically so both sides wear evenly.

Components Of A Mattress

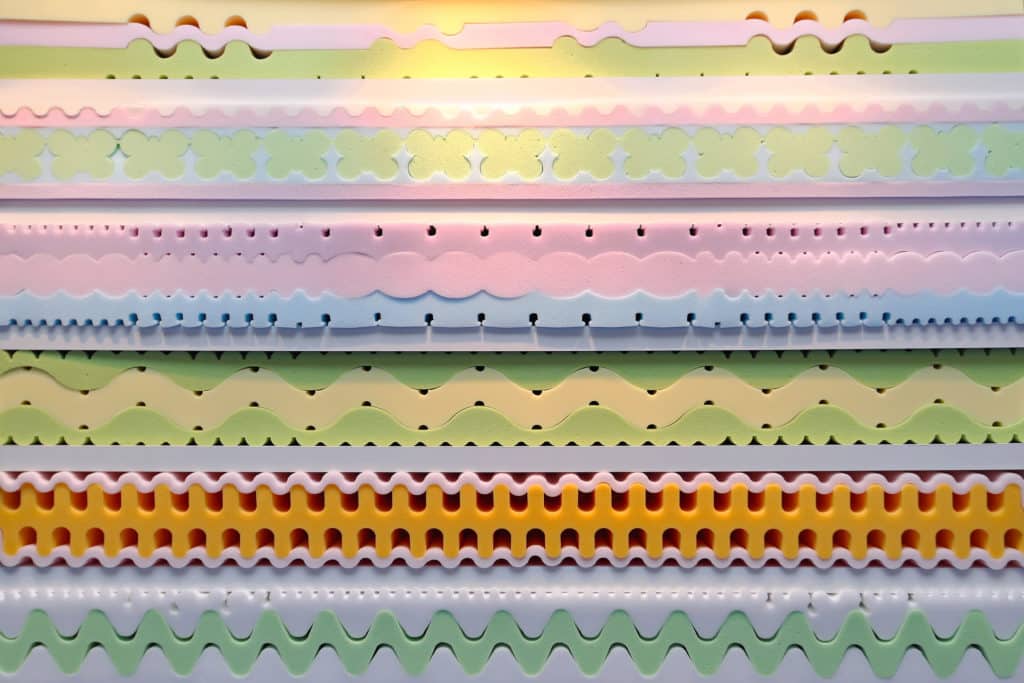

Despite the variety of mattress types available, all mattresses are essentially made up of the same components. From memory foam mattresses to spring, a mattress typically consists of layers of foam and cushioning materials. To understand how mattresses are made, it is important to look at each component and how they work together.

The bottom layer of most mattresses is composed of support foam or coil springs. This provides the foundation that supports the rest of the layers and prevents mattress sagging. Above this base layer, cushioning layers such as polyfoam, gel foam, or memory foam are added for comfort and pressure relief. Memory foam is particularly popular because it contours to the body’s shape for optimal comfort and support. However, depending on your preferences and budget, there are other cushioning materials available as well.

The topmost layer is usually composed of upholstery fabric or a quilt cover with padding underneath for an extra layer of comfort. The type and amount of material used in this layer varies depending on the specific mattress model and manufacturer’s design specifications. All these components come together to create a mattress tailored to different needs and preferences while also adhering to industry standards for quality control and durability.

With proper use, maintenance, and care, a good quality mattress should last between seven to ten years before you need a replacement. By understanding how mattresses are made and what materials they contain, consumers can make better decisions when choosing their next mattress based on their individual needs and budget constraints.

Materials Used In Manufacturing

The materials used to make a mattress vary depending on the type of mattress. Hybrid mattresses, for example, are typically made with a combination of natural materials and spring mattresses. Mattress fabrics are usually made from polyester, cotton or a blend of both materials. Upholstery layers are often constructed with polyurethane foam or latex foam, which is designed to provide comfort and support. The cell structure of the foam allows air to circulate through the mattress, helping regulate body temperature while sleeping. A typical mattress may also contain memory foam, wool and other natural fibers in its upholstery layer. Spring mattresses are the most common type of mattress available today. They use steel coils that offer superior support and durability. The coil system helps distribute weight evenly across the bed surface and provides individualized support based on each person’s body shape and size.

Processes Involved In Making A Mattress

According to statistics, around 1 in 3 Americans have sleep problems due to uncomfortable mattresses. To ensure that customers get the best value for their money, mattress manufacturers employ a range of processes in making a quality mattress. The entire mattress is made up of several components, including a quilted cover and materials such as body weight foam and extra sturdy coils.

House coils are used by many mattress manufacturers to create an even sleeping surface, while slow-sinking pressure relief is designed to reduce body pains and aches. The foam used in mattresses also helps absorb body heat to ensure maximum comfort during sleep. Additionally, true pressure relief technology is incorporated into some mattresses to provide additional support and comfort.

After all the components have been assembled together, they are tested for quality assurance before being shipped out to stores or customers. This ensures that each mattress meets the highest standards of comfort and durability before it reaches its destination. With this level of attention to detail, consumers can rest assured that their mattresses will provide them with years of comfortable sleep.

Factory Production Of A Mattress

The mattress industry is constantly evolving to meet the needs of consumers. Mattress manufacturers have developed a wide variety of mattresses to suit every sleep position and body type, while also taking into account motion transfer and body heat retention.

A typical mattress will have several layers of upholstery and cushioning materials, such as foam, latex or coil springs, which are placed in order from the firmest at the bottom, to the softest at the top. The largest mattress manufacturers usually produce their own foam for use in their products. This foam is made from polyurethane or other synthetic materials that are treated with various chemicals to make them more durable and resistant to dust mites and allergens.

Once all of the layers have been assembled, they are then covered with a fabric outer layer that helps protect the mattress from dirt and moisture. Then it’s ready for packaging or delivery to a store. This is how mattresses are made – from raw materials to finished product.

Customization Options For Consumers

When it comes to mattresses, customization options for consumers are plentiful. Online mattress companies, box mattress companies and many other retailers offer a wide range of mattresses to suit any budget and sleeping style. For those looking for a medium firm mattress, there is a great selection of medium soft to medium mattresses available. If you’re looking for something softer, there are plenty of cheap mattress options that provide excellent comfort. In addition, many mattresses come with advanced features such as curve-conforming pressure relief or extra pressure relief along the ribs for even greater comfort.

Transitional layers are also available in some mattress models which provide the ultimate in comfort and support. This type of layer helps to create the perfect balance between softness and firmness, allowing sleepers to enjoy the best of both worlds when it comes to their sleeping experience. Additionally, many manufacturers offer customizable features such as adjustable air beds or heat-sensitive foams that allow customers to tailor their sleep experience even further.

No matter what kind of mattress you’re looking for, there’s sure to be an option that meets your needs and fits within your budget. With so many customization options available today, anyone can find the perfect mattress that will give them the most comfortable night’s sleep possible at an affordable price.

Quality Assurance Tests And Standards

While it would seem that mattress production consists of a simple process of stuffing a few materials into a cover and calling it a day, in reality there is much more involved. Quality assurance tests and standards are essential to ensure that the mattresses produced live up to their promise of providing an excellent quality of sleep.

These tests examine the mattress’s ability to support the body in different positions for extended periods of time, as well as its resistance to deterioration over time. Expert personnel are employed to test each individual model that is released on the market, including expensive models which are tested over a year-long trial period instead of just one night. They also check whether or not thicker coverings can be used on mattresses designed for stomach sleepers without causing too much discomfort.

At the end of all these tests, only products that meet all the required standards are allowed to be published for sale. That is why customers can rest assured about the quality of mattresses they purchase – even if they don’t know exactly how they’re made.

Packaging And Delivery Processes

After the mattress is made, it must be packaged and delivered to its destination. Dozens of mattresses can be shipped together in one box. For an online all foam mattress, the mattress is compressed in a box and shipped directly to the consumer’s door. If a broken or worn out mattress needs to be replaced, a new one can be conveniently ordered online from many consumer online mattress companies.

When comparing sleep quality, consumers should consider choosing a pillowy surface for extra cushioning or a surface that provides spine alignment for better support. The bedding industry has been revolutionized by consumer online mattress companies offering cushy mattresses with free shipping and returns. Many of these companies also offer flippable two piece mattresses that are designed to reduce motion transfer for couples sharing a bed.

Overall, consumers should be aware of their specific needs and do research on the helpful features offered by various consumer online mattress companies before making their purchase decision. Doing this will help them find the right fit for their individual comfort preferences and sleeping habits.

Recycling And Reusing Old Mattresses

Transitioning from discussing the packaging and delivery processes of mattresses, recycling and reusing old mattresses is an increasingly popular business model. It’s like a caterpillar transforming into a butterfly; outdated mattresses are broken down and recycled to be reborn as something new.

The process of mattress recycling and reusing old mattresses begins with dismantling them in order to separate the different components, such as foam, fabric, springs, and wooden frames. After separating the individual parts, they are sent to specialized facilities for reprocessing. The foam is shredded and melted down into pellets that can be reused for insulation or other products such as carpet padding or mattress underlayment. The wood is also shredded down into wood chips which can be used for animal bedding or garden mulch. Fabric pieces are often sold to companies that use them to make furniture fabrics or rugs. Springs can be reused in new beds or re-purposed into metal artworks.

By repurposing these materials, mattress companies are not only helping to reduce waste but also providing affordable options for those seeking low-cost alternatives when buying a mattress. This business model helps keep costs low while still maintaining high quality standards for their customers—a win-win situation for both the environment and consumers alike!

Recycling and reusing old mattresses may not be the most glamorous practice, but it’s certainly a smart one that benefits everyone involved. By doing this we’re able to take part in responsible consumerism while at the same time contributing to sustainability efforts around the world.

Environmental Concerns With Making A Mattress

The process of making a mattress has an impact on the environment. From the materials used to manufacture it, to disposing of the old one, a mattress’s environmental footprint is significant. It is important to consider the sustainability of each step in the production of a mattress.

One environmental concern about making a mattress is emissions from burning fossil fuels during manufacturing processes. This can include heat treatment, foam production and fabric dyeing. In addition, many mattresses are made with petroleum-based polyurethane foam, which is not biodegradable and requires large amounts of energy to produce. Other materials like cotton and wool may be organic but their harvesting can cause damage to ecosystems if they are not managed responsibly.

Finally, when it comes time to dispose of a mattress, most end up in landfills where they take years to decompose due to their chemical composition. In addition, some states have banned incineration or burning as a disposal method due to concerns about air pollution and hazardous byproducts. It is important for consumers to consider ways that their mattress can be recycled or reused instead of being sent off into a landfill.

Conclusion

As you can see, making a mattress is an involved process that requires the use of many materials. From the comfort layers to the support core, each component must be carefully crafted and tested for quality assurance. Ultimately, with factory production, packaging and delivery processes, mattresses are able to arrive at their destinations where they will keep us comfortable for years to come.

It’s important to note that there are environmental concerns associated with mattress manufacturing. This means it’s important for mattress companies to practice sustainability whenever possible by recycling and reusing old mattresses. As consumers, we can help reduce our environmental impact by researching mattress brands who prioritize ethical practices.

In conclusion, although making a mattress is an involved process with many components and materials used in production, it’s ultimately worth it when you get a good night’s sleep. With thoughtful consideration of sustainable practices and quality assurance tests, mattresses can bring us comfort while still being mindful of our environment.